CAMISMA: a lightweight seat structure based on thermoplastic FRP

Innovative materials with good weight-specific and mechanical properties as well as the appropriate use of materials in construction are essential to develop efficient vehicles with low emissions.

Carbon-fiber reinforced plastics (CFRP) therefore play an important role, thanks to their good mechanical characteristics. However, there is still a great need for research concerning their ecological and economical production and processing or the further use of fiber waste.

Multi-material construction combines the lightweight advantages of CFRP with standard cycle times of serial production at acceptable cost levels.

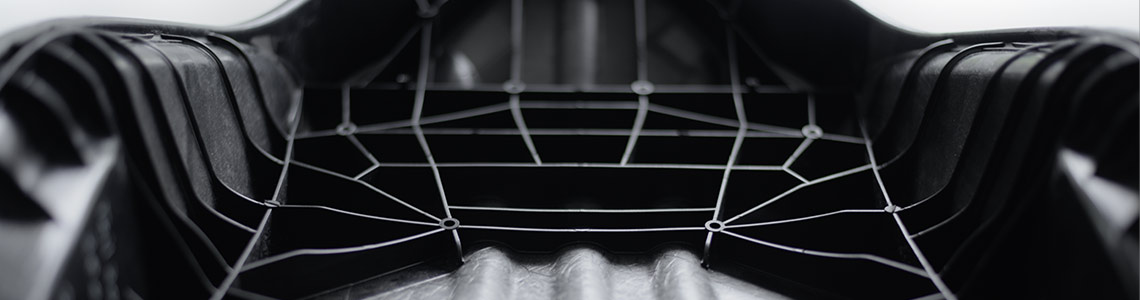

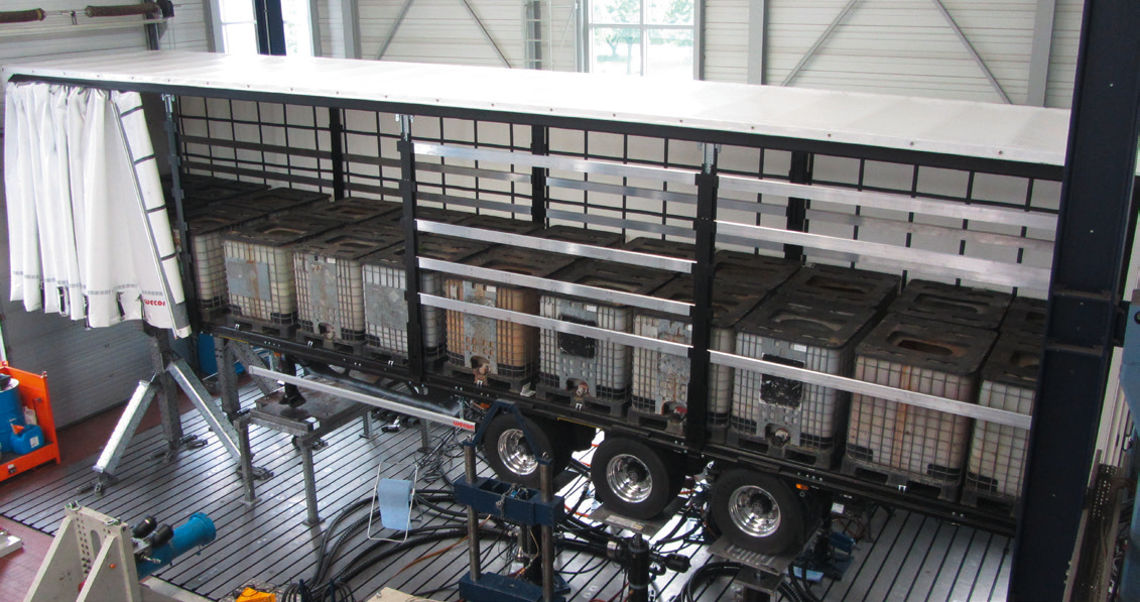

Within the project CAMISMA we created a hybrid sport seat backrest, which meets all relevant safety requirements and still is 50 % lighter than the serial reference seat. It was produced with a hybrid thermoforming injection process, and can be built for about 7 – 8 euro per Kilogram if set up as a serial production line with estimated 150,000 pieces per year.

With the help of our dynamic FEM simulations we analyzed and optimized the crash behavior of the backrest structure. Plus, we validated its properties in real crash tests with prototypes on our crash test bench.

fka World of Research

![[Foto: people working in the background with a abstract image of a process as overlay]](/images/artikel/MBSE/Model_Based_Systems_Engineering.png)

Model-Based Systems Engineering

Introduction and implementation of the Model-Based Systems Engineering (MBSE) approach

We move away from the traditional document-based approach and instead rely on interconnected digital models. A system model serves as a shared platform for communication between all teams involved in development. It acts as a central source of information, ensuring that crucial data is always up to date and accessible.

Read more ...

Strategy & Consulting |

Strategy Teaser

Exciting short studies on innovations and developments in the automotive industry by our experts from Strategy & Consulting.

Read more ...![[Foto: VW ID.3]](/images/artikel/bench/id3/vw-id3-IF2_2262.jpg)

Continuous Bechmarking

VW ID.3 Benchmarking

fka & FEV Consulting launched the comprehensive benchmarking program.

Read more ...

![[Foto: CAMISMA Lightweight Seat Structure]](/images/highlights/karosserie/camisma3.jpg)

![[Foto: CAMISMA Lightweight Seat Structure]](/images/highlights/karosserie/camisma4.jpg)

![[Foto: Ralf Matheis]](/images/personen/matheis-ralf.jpg)