![[Foto: Benchmarked Vehicles]](/images/artikel/bench/gesamt/gesamtfahrzeug-1140x300.jpg)

Full Vehicle Benchmarking Activity

In 2011 the continuous benchmarking of electric vehicles started with the analysis of the first high volume electric vehicle (Mitsubishi i-MiEV). The electric vehicles Nissan Leaf and BMW i3 followed in the years 2012 and 2014. The functional benchmarking focuses on the analysis of numerous technical properties. Within the design benchmarking, the vehicles are disassembled to component level and the resulting single parts are analysed regarding dimensions, weights, manufacturing and joining technologies as well as material usage.

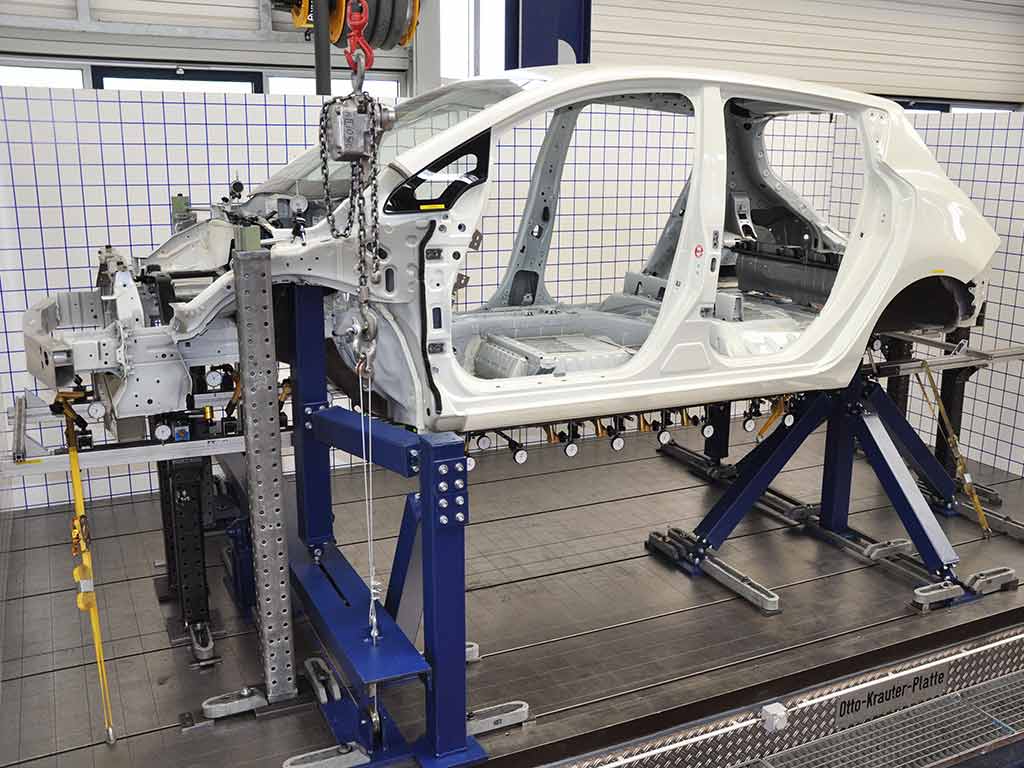

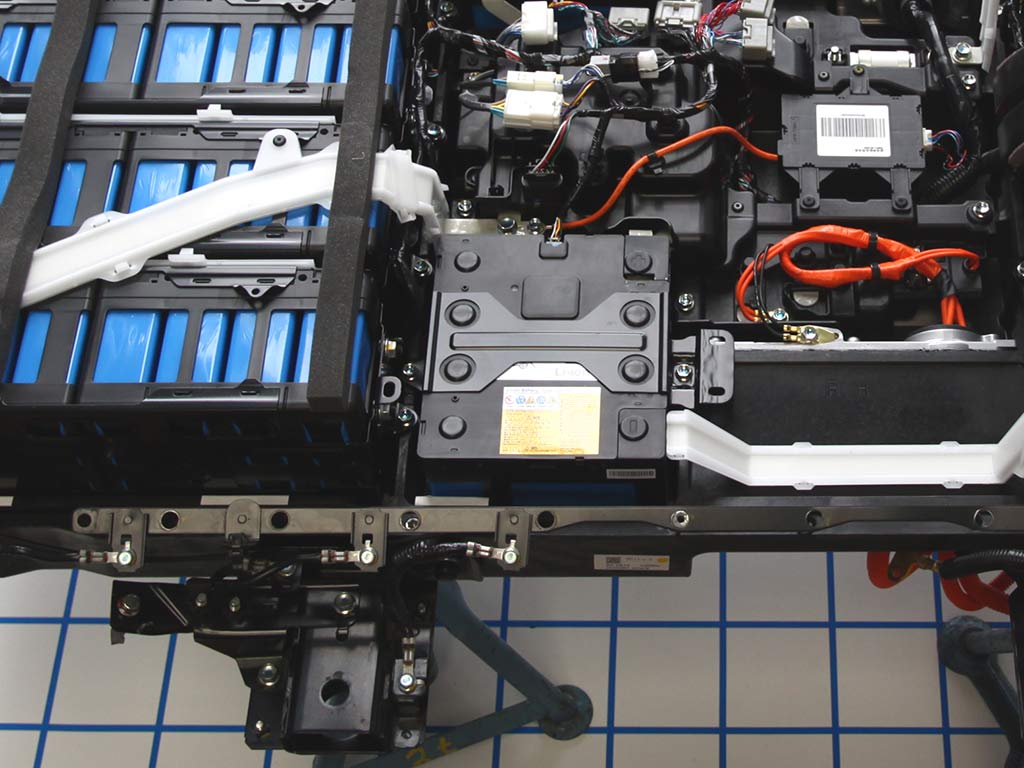

Within the full vehicle benchmarking, the vehicle domains chassis, drivetrain as well as electric/electronics are subjects of different tests and procedures. Within the chassis analysis, inertia parameters and the center of gravity are determined, k&c parameters as well as the damper characteristics are analysed and standardised road tests are executed. The functional benchmarking of the drivetrain includes the determination of the driving resistances and of the energy consumptions as well as the analysis of the vehicle range for different standardised driving cycles. In addition to that, the efficiency of the electric drive and of the high voltage components are analysed and the high voltage battery is characterised in detail. Within the area electric/electronics, the 12V main power supply as well as the high voltage main power supply are analysed in detail. In doing so, stability and package analyses are being conducted and charging/discharging processes are recorded. The body-in-white is analysed regarding eigenfrequencies and static stiffnesses (bending and torsion). Further acoustic topics (e.g. interior and exterior noise measurements for different driving operations, e.g. accelerated passing) are considered.

After the functional testing, the vehicles are disassembled to component level. The single parts are cataloged, named (by the use of a standardised nomenclature) and analysed regarding dimensions, material usage, weights and joining techniques. A detailed photo documentation is also part of the design benchmarking process.

For more pictures in the galleries please click on one of the pictures.

Ihr Ansprechpartner

Your contact

![[Foto: Roland Wohlecker]](/images/personen/wohlecker-roland.jpg)

Dr. Roland Wohlecker

Manager Structural Assessment & Testing

This email address is being protected from spambots. You need JavaScript enabled to view it.

Telefon: +49 241 8861 191

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 241 8861 191

fka-Benchmarking-Datenbank

fka benchmarking database

Tesla Model 3

fka starts benchmarking of the Model 3 and offer exclusive insights into the technology of the newest Tesla.

![[Foto: people working in the background with a abstract image of a process as overlay]](/images/artikel/MBSE/Model_Based_Systems_Engineering.png)

![[Foto: VW ID.3]](/images/artikel/bench/id3/vw-id3-IF2_2262.jpg)