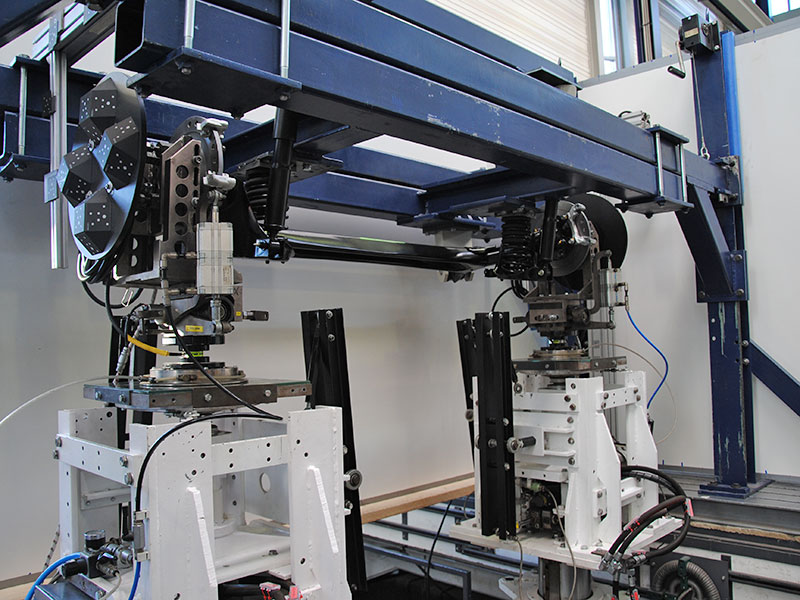

Kinematic and Compliance Test Rig (K&C)

The kinematics and compliance (K&C) characteristics of a chassis system have major influence on the vehicle driving behavior and the overall vehicle performance. Therefore for the understanding and development of innovative and future-oriented chassis systems an exact knowledge of the K&C characteristics is necessary.

fka offers a longstanding expertise in the identification of the kinematics and compliance characteristics and access to a state-of-the art K&C test rig capable for measurements of full vehicles or stand-alone axle subsystems. The K&C test rig allows a three-dimensional force application (longitudinal, lateral and vertical forces) via air-bedded wheel substitute systems adapted to the particular wheel parameters. The resulting displacements and wheel angle changes are measured and recorded with a high-precision optical measurement system. For special measurement tasks additional sensors (e. g. travel sensors or wire strain gauges) can be integrated into the measurement chain.

K&C test bench – technical information

Test bench features:

- Air-bedded wheel substitute systems (adjustable to the particular wheel parameters)

- Controlled motion of the suspensions (compression & rebound) and application of forces (longitudinal & lateral forces) via twelve independent actuators

- Max. vertical forces: 13.000 N

- Max. horizontal forces: 5.000 N - High-precision optical measurement system (AICON WheelWatch) for recording of the resulting displacements and wheel angle changes

- Capability to perform axle subsystem as well as full vehicle measurements

Measured K&C parameters:

- Tyre contact point displacement (x, y, z)

- Wheel center displacement (x, y, z)

- Toe & camber angle changes

- Roll center position (calculated)

- Steering ratio

- Caster angle changes during longitudinal force application

Vehicle limitations:

- Max. vehicle track width: 1.640 mm

- Max. vehicle wheel base 3.210 mm

- Special measurement configurations with vehicles beyond the stated limitations are upon request

Our services

Measurement preparations:

- Vehicle conditioning (e. g. loading with passenger dummies or dummy payload)

- Design & manufacturing of vehicle specific fixation adapters (if necessary)

- Application of additional sensors (e. g. to measure steering rack, spring or damper travel)

- Test bench preparation

Performance of K&C-measurements

- Performance of K&C-measurement on full vehicles or axle subsystems

- Parallel & opposite wheel travel measurements

- Steering measurements

- Lateral force application

- Longitudinal force application - Optical measurement & recording of relevant K&C parameters

Data and test evaluation:

- Post-processing & evaluation of recorded measurement data

- Determination characteristic suspension parameters

- Preparation of detailed test documentation

- Generation of model-specific K&C-parameter files for common simulation tools

Your testing demand

You are welcome to contact us for an individual solution for your demands in the field of K&C parameter identification

Ihr Ansprechpartner

Your contact

![[Foto: Daniel Wegener]](/images/personen/wegener-daniel.jpg)

Dr. Daniel Wegener

Head of Chassis & NVH

This email address is being protected from spambots. You need JavaScript enabled to view it.

Telefon: +49 241 8861 187

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 241 8861 187